Are you a pharma expert planning to expand your pharmaceutical product segment to effervescent tablets? If yes, then you must read this informative blog!

People often come across ads on social media that promote effervescent tablets. Those tablets magically dissolve into the glass of water, giving an extra effect to the advertisement and the audience goes WOW! They wonder how and why these tablets are consumed. Well, all, including medical professionals, love this newer, faster, and more convenient way of consuming medications and supplements.

These tablets can dissolve quickly in water. This makes them easier to ingest and enhances absorption. However, manufacturing along with effervescent packaging isn’t straightforward. Since they are highly sensitive to moisture, they require precise formulation and hence demand specialized effervescent packaging to maintain their effectiveness.

The way an effervescent tablet dissolves in water is magical. As soon as you drop it into water, it releases carbon dioxide, creating a fizzy solution that enhances solubility and taste. Secret? Active ingredients along with effervescence-inducing compounds like citric acid and sodium bicarbonate.

As mentioned above, the magical reaction of effervescent tablets after dropping into water makes them a preferred choice for pharmaceuticals and nutraceuticals. However, such stability and proper dissolution comes after precision at every stage. Especially during effervescent packaging. So, how can one achieve it? Well, keep reading!

1. Formulation & Blending

Active ingredients, excipients, and effervescent agents in effervescent tablets need to be carefully blended and balanced to ensure uniformity. This blend must be dry, free-flowing, and moisture-resistant to prevent premature reactions.

2. Granulation

One Of the important steps in the process of effervescent tablet manufacturing is Granulation. It improves powder flow and ensures consistent tablet weight and hardness. Granulation also enhances dissolution properties for a uniform fizzy effect.

3. Compression

In this step, tablets are pressed with the right amount of pressure. Neither too much, nor too less.

4. Drying

Drying is an important step in the manufacturing of effervescent tablets as the residual moisture can trigger premature effervescence. Hence it requires a controlled drying process which extends shelf life and preserves tablet integrity.

5. Optional Coating

Though optional, a protective coating can reduce moisture absorption and improve handling. Hence, it is recommended to coat your effervescent tablets to ensure longer-lasting stability.

What happens if these magical tablets catch moisture? They’ll be ruined! So, Protecting tablets from moisture with the right packaging is the key!

1. Moisture-Resistant Seals

Firstly, each tablet needs to be protected from humidity to maintain its fizzing capability.

2. Blister Packs & Tubes

Secondly, protecting tablets with blister packs and tubes with desiccants will prevent moisture buildup.

3. Tamper-Proof Designs

Thirdly, it’s important to seal effervescent tablets to prevent contamination and maintain product integrity.

4. Consumer-Friendly Packaging

Last but not the least, consumer-friendly processing and effervescent packaging solutions for effervescent tablets is a game changer. One must go for easy-to-open designs and clear labeling to ensure a smooth user experience.

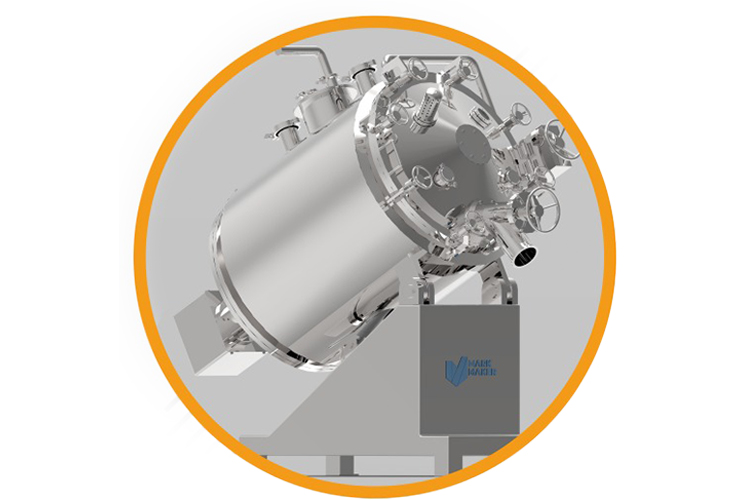

One of the leading manufacturers in India, Mark Maker Pharma offers indigenous solutions for effervescent tablet production. Their expert team not only excels at processing but also packaging effervescent tablets. Since all their machines are backed by updated technology, they retain the effectiveness of effervescent tablets from production to consumption.

The manufacturing and packaging for effervescent tablets come with many challenges and here’s how Mark Maker Pharma can address them:

Moisture Sensitivity

Issue: High humidity can spoil tablets, cause premature reaction.

Solution: Low-humidity production environments, desiccants, and hermetic packaging

Tablet Dissolution Consistency

Issue: When formulation differs, dissolution rates may be affected.

Solution: Utilization of high precision blending and granulation processes allows for even effervescence.

Strength vs. Rapid Dissolution

Issue: If tablets are over-compressed, they become too hard and slow the dissolution process.

Challenge: Large molecules can be hard to process

Solution: State-of-the-art compression techniques keep structure and takes less time to dissolve.

Production process and Low cost for scalability

Issue: To manufacture products on a large scale at a lower cost.

Challenge: Increasing production while keeping costs low.

Solution: Processing raw materials into final products and packaging.

Future Trends in Processing and Packaging for Effervescent Tablets

The current trend of consuming effervescent tablets seems to stay in the market for a longer run. For such a burgeoning market, producers must consider its high demand due to convenient, fast-acting supplements and medications.

1. EFF-PRO

Granulation, Drying & Blending – All in One

2. VACUUM TRAY DRYER

Strengthens Tablets, Extends Shelf Life

3. EFF-PACK 100

High-Speed Tube Filling for Mass Production

4. EFF-PACK 4T & 8T

Optimized for High-Demand Markets

5. EFF-PACK SA

Compact & Efficient for Small Batches

Effervescent tablet manufacturing is beyond mixing ingredients and pressing tablets. It needs careful formulation, controlled processing, and robust packaging to ensure the quality and effectiveness are intact. If you’re looking for customised packaging solutions for effervescent tablets, Mark Maker Pharma has got your back. They help pharmaceutical and nutraceutical companies produce high-quality effervescent tablets that stay fresh and effective. Partner with Mark Maker Pharma today to avail of industry-leading processing and packaging solutions.