From the initial concept to the plant survey and manufacturing of the equipment and systems, Mark Maker has the experience and knowledge to get your process online today.

In-house designing services, manufacturing and consulting approach gives us an edge over the competition.

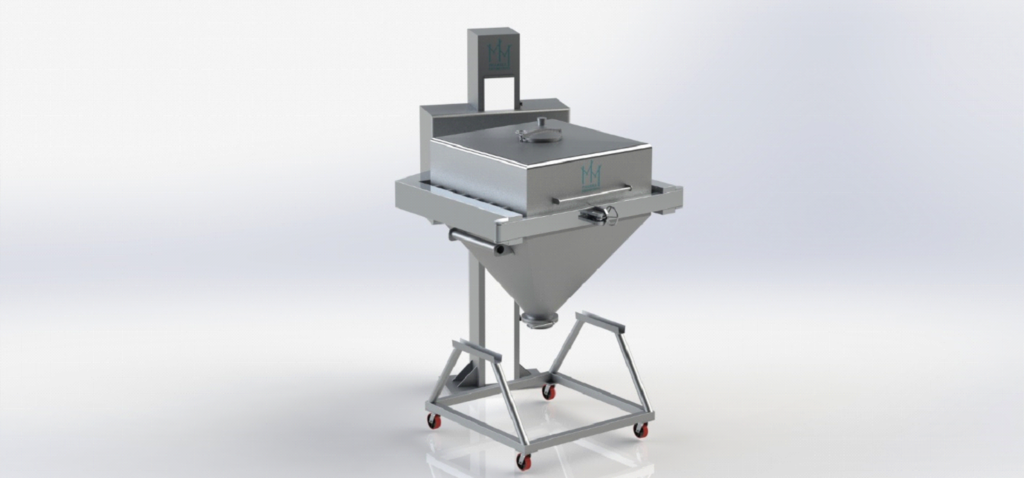

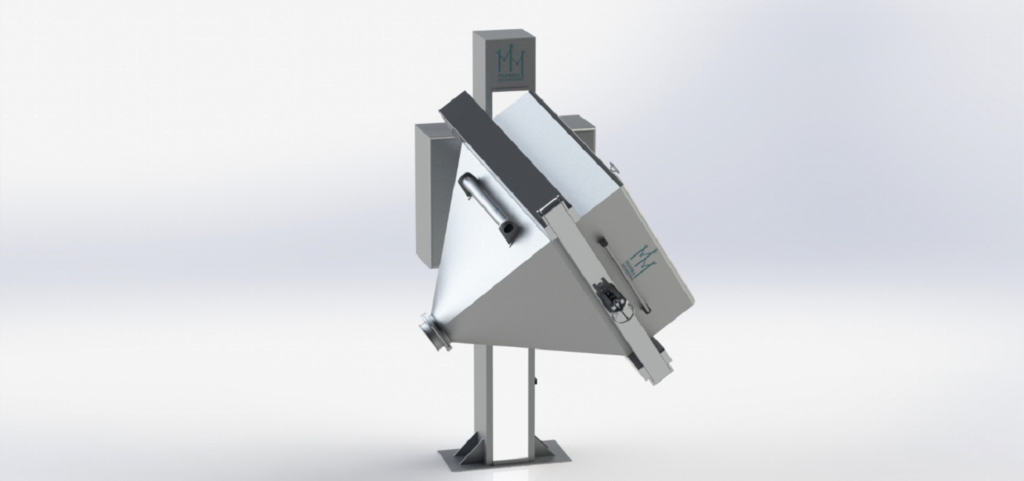

| MODEL | Gross Capacity in (Ltrs) | Working Capacity in (Ltrs) | Motor HP | Hydraulic lifting power |

|---|---|---|---|---|

| MM CB-150 | 150 | 120 | 1.5 x 2 | 2 HP |

| MM CB-300 | 300 | 240 | 2 x 2 | 2 HP |

| MM CB-750 | 750 | 600 | 3×2 | 2 HP |

| MM CB-1250 | 1250 | 1000 | 7.5x2 | 3 HP |

| MM CB-1500 | 1500 | 1200 | 7.5x2 | 3 HP |

| MM CB-2000 | 2000 | 1600 | 10x2 | 3 HP |

| MM CB-3000 | 3000 | 2400 | 15 x 2 | 5 HP |