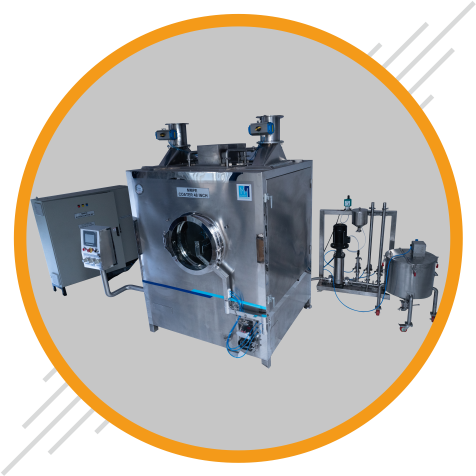

Tablet Coating

PRODUCTION EQUIPMENT

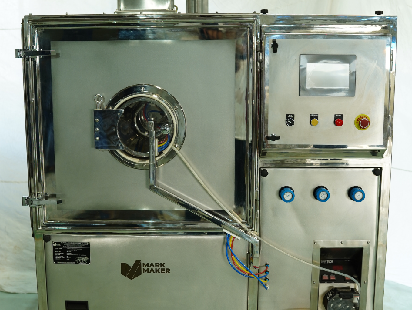

- Designed to carry out most efficient and uniform coating with the minimum human intervention. totally enclosed unit, with in built WIP system.

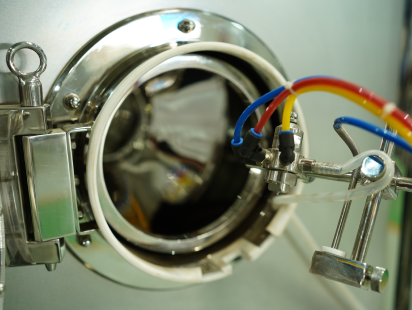

- Its interiors are accessible through leak proof doors provided on rear, left and right sides.

- The unique perforated coating pan design utilizes a totally enclosed, highly efficient air flow system for maximum drying uniformity and minimum process time.

- CFM controlled through sensors and VFD’s accurately.