Tablet Coating

PRODUCTION EQUIPMENT

- Designed to carry out most efficient and uniform coating with the minimum human intervention. totally enclosed unit, with in built WIP system.

- Its interiors are accessible through leak proof doors provided on rear, left and right sides.

- The unique perforated coating pan design utilizes a totally enclosed, highly efficient air flow system for maximum drying uniformity and minimum process time.

- CFM controlled through sensors and VFD’s accurately.

KEY FEATURES

- Designed as per cGMP, USFDA, UKMHRA

- Complete separation of production and technical area.

- Fully automatic aqueous and non-aqueous film coating process monitored and controlled by PLC.

- Extremely user-friendly software and operation through soft touch HMI 21CFR Part II compliant, SCADA Compatible (Optional)

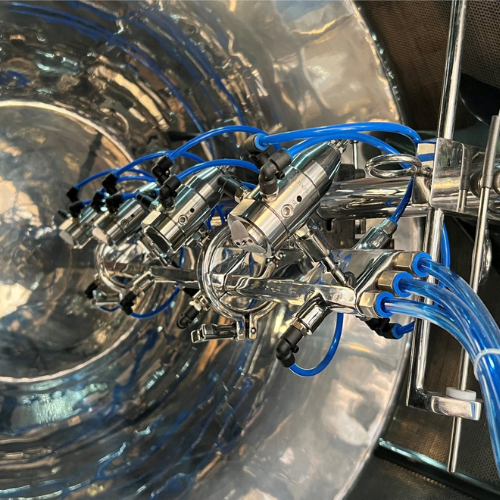

- Perforated Pan, Washing sink, Inlet air plenum, Exhaust air plenum with air tight door.

- Fully perforated pan ensures perfect air flow used for drying and coating.

- Special Ear type removable baffles provided inside pan for tumbling tablet for uniform coating.

- Glass Pan door for Process monitoring.

- Tri-clover joints for ease of cleaning during the changeover.

- 100% Washing in place with help of Spray balls and mobile skid.

- Inbuild centrifugal pump for recirculation of cleaning water.

MODEL | MMPE AC-30″ | MMPE AC-36″ | MMPE AC-48″ | MMPE AC-60″ |

|---|---|---|---|---|

Pan Dia | 760MM | 920MM | 1220MM | 1524MM |

Pan Mouth Dia | 330MM | 480MM | 520MM | 550MM |

Working capacity | 27 KG | 61 KG

| 130 KG

| 250 KG

|

Pan Drive Motor | 2 HP | 3 HP | 5 HP | 7.5 HP |

Inlet Blower Motor | 3 HP | 5 HP | 5 HP | 7.5 HP |

Outlet Exhaust Blower | 5 HP | 12.5 HP | 15 HP | 25 HP |

Heating Arrangement | Through Electrical Heater / Steam Coil | |||