INTEGRATED WET GRANULATION

Laboratory: 1 Kg to 10 Kg | Production: 30 Kg to 250 Kg

Maximum Solution in minimum space with limited manpower.

MM’s Integrated wet granulation offers versatile process for laboratory and production for pharmaceutical and nutraceutical products.

Complete line is best suitable for laboratory or clinical trials with minimum space with reduced cross contamination risks.

Robust design with separation of production and maintenance area with CIP-WIP provisions.

An Integrated wet granulation process made with combination of High Shear Mixer, Fluid Bed processor or coater, milling and blending all at oneplace with dust free transfer solutions together, which can also be upgraded to contained granulation. process for working oncological products.

The entire process is carried out under closed condition to avoid exposure to air, humidity or contamination.

User-friendly centralised operating panel with advance HMI programmed as per 21CFR part 11. SCADA based programming logic can also opted optionally.

KEY FEATURES

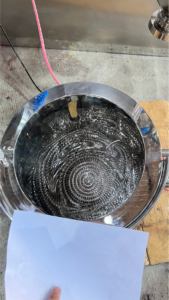

Multi process Fluid Bed system (Drying, Granulation and Coating) with conidor type bottom plate for efficient drying and processing, with online sampling arrangement.

Contained transfer under vacuum with ease of cleaning in place arrangement.

Dry cone milling with grated sieves.

We offer services with installation support, commissioning, process validation with complete training and technical assistance.

Interchangeable bowls for Lab RMG from 2 liters to 15 liters.

Peristaltic pump for spraying binder solution in RMG.

Venturi based (air operated) vacuum transfer system ensures no extra piping works on suck and dump principle.

Multi attached Blending system offer various shapes of bins interchangeability for Lab designs.

DISSOLUTION