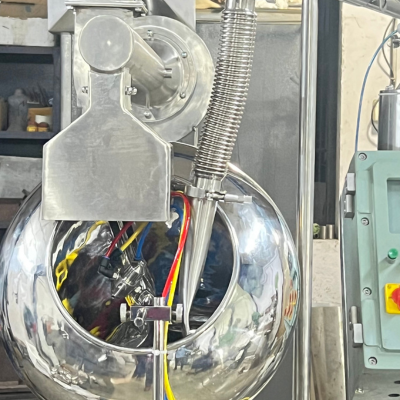

COATING PAN

R&D and Production Equipment

The utility of a coating pan allows for the creation of an aqueous or organic film coat around the pellets. A semi-ellipsoidal pan with a circular cover is one of the parts of this device that makes it easier to charge and discharge tablets. With the assistance of a motor and a gear, this pan is rotated.

KEY FEATURES

- Coating system for manual film coating and sugar coating also available.

- Baffles either welded or detachable (welded are the standard supply if notspecified)

- Easy mounting arrangement considering changeover of coating/polishing pan.

- Separate mobile Hot Air Blower System is provided for easy operation

- Digital Temperature Controller provided with necessary temperature control device with interlocking for heater function.

- All courts AISI 316/304 &non-contact parts AISI 304.

- Maxine is designed with fabricated structure fitted with SS enclosure which makes simple, cleanablecovering and mounted on anti-vibration pad

- Easy to replace polishing pan and other size coating pan

- cGMP design for ease of cleaning.

- Explosion proof / Flame Proof

- CE Certified.

TECHNICAL SPECIFICATION

MODEL | MMCP-8” | MM CP-12” | MM CP-18” | MM CP-24” | MM CP-30” | MM CP-36” | MM CP-48” | MM CP-60” |

|---|---|---|---|---|---|---|---|---|

Pan Mouth Dia | 120 mm | 175 mm | 250 mm | 300 mm | 425 mm | 640 mm | 520 mm | 550 mm |

Working capacity | 0.15 Kg | 500 gm To 800 gm

| 2 Kg To 4 Kg

| 4 Kg To 12 Kg

| 27 Kg | 61Kg | 130 Kg | 250 Kg |

Pan Drive Motor

| 1 HP | 2 HP | 2 HP | 5 HP | 7.5 HP | |||

Inlet Blower Motor | 1 HP | 3 HP | 3 HP | 5 HP | 7.5 HP | |||

Outlet Exhaust Blower | 1 HP | 5 HP | 5 HP | 7.5 HP | 10 HP | |||

Heating Arrangement | Through Electrical Heater / Steam Coil | |||||||